Pressure wound prevention and care continue to be a major challenge in Aged Care and Hospital Care settings across the globe.

According to data presented in the final Australian Aged Care Royal Commission Report 2021, in the last quarter of 2019-20, residential care providers reported 11,988 observations of pressure injuries under the National Aged Care Mandatory Quality Indicator Program. With 176,657 people assessed for pressure injuries, there was an average of 6.79 observations of pressure injuries per 100 residents assessed.

It is broadly accepted that the main causes of pressure ulcers are a combination of factors related to pressure, sheer, friction and microclimate. While prolonged pressure has long been understood as perhaps the key factor in the development of pressure ulcers, sheer, friction and microclimate are increasing areas of focus and research.

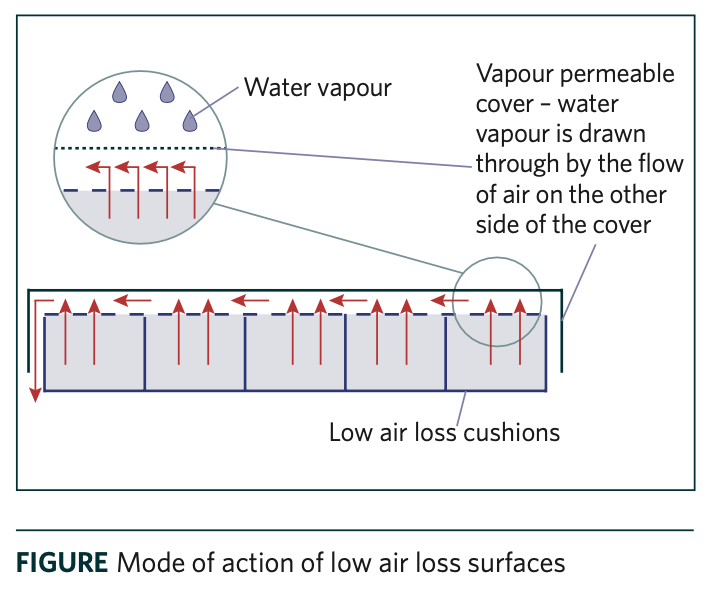

Perhaps the least well understood of these contributing factors is the role of microclimate. According to the International Review of Pressure Ulcer Prevention published by Wounds International 2010, “In the context of pressure ulcers, microclimate usually refers to skin temperature and moisture conditions at the skin– support surface interface”. The report goes on to state that “….extremes of skin temperature and/or humidity/skin moisture appear to increase the sensitivity of skin to the damaging effects of pressure, shear stresses and friction” and that “…the overall aim of microclimate management should be to avoid extremes of temperature or skin moisture and to enhance patient comfort.”

Effective microclimate control necessitates support surfaces that facilitate air and vapour transfer to draw moisture away from the skin surface and maintain ideal skin temperature. With regard to polyurethane coated textiles, this feature is commonly referred to and measured in terms of breathability. The challenge for quality producers is that increased breathability can often come only at the expense of essential performance in waterproofness and chemical resistance. One measure of a quality polyurethane coated textile producer is the ability to strike just the right balance between these competing requirements and then to continually push those limits.

At Carr Group, enhanced breathability and chemical resistance have long been defining features and a core focus of our Carrflex Mediplus and Carrflex Extreme barrier textiles. We identify and collaborate with only the best producers to continually drive new product development in our polyurethane coatings. We believe that it is not only essential to understand the clinical needs of the market today but also to drive innovation towards the clinical needs of tomorrow, as we steadily unravel the mysteries of microclimate.